Streamline Bulk Packaging with Jumbo Bagging Systems

December 13, 2024

Efficient packaging is vital in industries managing bulk materials. Jumbo Bagging Systems, or FIBC, offer reliable solutions....

Read MoreEfficient material handling systems are the backbone of any successful packaging operation, ensuring a smooth and automated workflow. Payper India offers advanced feeder systems designed to optimize bulk material flow, enhancing precision, speed, and reliability. These high-performance feeders handle a wide range of materials, including granules, powders, and irregularly shaped products, ensuring consistent and accurate feeding. With automated weighing technology and high-speed material dispensing, they reduce manual intervention, minimizing errors and boosting operational efficiency. Their versatile and modular design allows seamless integration into industrial bagging and weighing systems, making them ideal for bulk packaging solutions. Built with heavy-duty components, they ensure long-term durability, low maintenance costs, and maximum throughput. The feeders come with adjustable feeding settings, allowing customization based on material density, flow rate, and packaging requirements. A dust-controlled feeding mechanism maintains a clean, hygienic, and contamination-free environment, ensuring compliance with industrial safety standards. Suitable for industries such as chemical processing, agriculture, food production, plastic manufacturing, and construction materials, these systems improve packaging accuracy, reduce product waste, and enhance supply chain efficiency. Payper India’s feeder systems are the ultimate solution for businesses aiming for automation, precision, and increased productivity in bulk material handling.

Feeder systems offer exceptional flexibility, efficiently handling materials ranging from free-flowing grains to cohesive powders in bulk packaging operations. Their adjustable flow rates and customizable feeding mechanisms optimize performance for various material densities and textures, ensuring clog-free processing. With automated material flow control, they enhance weighing accuracy, minimize product waste, and improve packaging efficiency. These systems seamlessly integrate with industrial bagging and weighing solutions, supporting high-speed, dust-free operations for a cleaner and more productive workspace. Ideal for industries like chemical processing, food manufacturing, agriculture, and construction, they enhance operational reliability and supply chain efficiency.

Feeder systems are designed to ensure precise dosing and weighing, minimizing material waste and maximizing efficiency in bulk packaging operations. With advanced weighing technology and automated controls, they provide consistent and accurate measurements for various materials, including powders and granules. heir high-precision sensors and flow regulation mechanisms reduce errors, ensuring optimal product consistency and quality. By integrating seamlessly with industrial bagging and weighing systems, they enhance production accuracy while reducing operational costs. Ideal for industries such as food processing, chemicals, agriculture, and construction, these systems improve packaging precision, reduce product loss, and enhance overall productivity..

Feeder systems are built with high-quality, robust materials to withstand the demanding conditions of industrial environments. Their heavy-duty construction ensures long-lasting performance, even in high-throughput operations involving abrasive or dense materials. Designed for minimal wear and tear, these systems require low maintenance, reducing downtime and operational costs. Corrosion-resistant and engineered for stability, they maintain efficiency in harsh conditions such as chemical processing, mining, and bulk material handling. With a focus on reliability, these feeders provide consistent performance, making them a valuable investment for industries requiring durable and efficient material handling solutions.

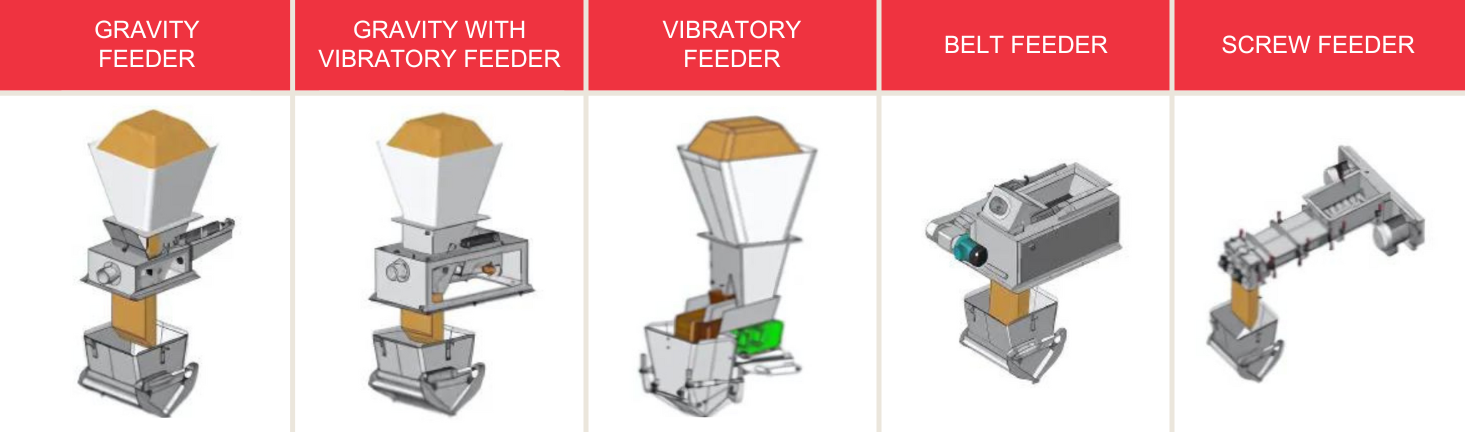

Feeder systems are available in multiple configurations, including gravity, screw, belt, and vibratory feeders, to cater to specific material handling requirements. Each type is designed to optimize the flow of different materials, from fine powders to coarse granules, ensuring smooth and precise feeding. Gravity feeders provide a simple, energy-efficient solution, while screw feeders offer controlled dosing for bulk powders. Belt feeders ensure a steady material flow, and vibratory feeders are ideal for fragile or irregularly shaped products. With customizable designs and automation options, these feeders integrate seamlessly into various industrial processes, enhancing efficiency and accuracy.

Feeder systems play a crucial role in the agriculture industry by efficiently handling seeds, grains, and fertilizers with precision and reliability. Designed to accommodate a variety of bulk materials, they ensure smooth and consistent flow, reducing blockages and material loss. Advanced weighing and dosing mechanisms help maintain accuracy, optimizing the packaging and distribution process. With dust-controlled operations, these feeders create a cleaner and safer working environment, minimizing contamination risks. Ideal for farms, seed processing plants, and fertilizer manufacturers, they enhance productivity while ensuring high-speed and efficient bulk handling.

Feeder systems are designed to safely handle a wide range of chemical powders and granules, ensuring precise and controlled material flow. Built with corrosion-resistant materials, they withstand harsh chemical environments while maintaining efficiency and longevity. Advanced dosing and weighing technology help prevent material loss, ensuring accurate measurements and reducing waste. With dust-controlled and enclosed feeding mechanisms, these systems minimize contamination risks and improve workplace safety. Ideal for chemical processing plants, pharmaceutical industries, and specialty chemical manufacturing, they enhance operational efficiency while complying with industrial safety standards.

Feeder systems are essential for the construction industry, efficiently handling bulk materials such as cement, sand, and aggregates. Designed for high-capacity operations, they ensure a steady and controlled material flow, minimizing waste and maximizing productivity. Their durable, heavy-duty construction withstands harsh environments, ensuring long-term reliability in demanding conditions. With precise weighing and dosing mechanisms, these feeders enhance accuracy in batching and mixing processes, improving material consistency. Ideal for cement plants, concrete production, and bulk material handling facilities, they optimize workflow and contribute to a more efficient and cost-effective operation.

With over five decades of expertise, Payper India has established itself as a trusted leader in designing and manufacturing advanced weighing and bagging solutions. Commitment to quality and innovation ensures that Feeders deliver exceptional performance, precision, and efficiency across various industries. These automated solutions are built for reliability, optimizing material feeding operations while minimizing downtime and labor costs. Additionally, robust after-sales support guarantees seamless operations, providing long-term assistance and maintenance to ensure continued productivity and operational excellence.

December 13, 2024

Efficient packaging is vital in industries managing bulk materials. Jumbo Bagging Systems, or FIBC, offer reliable solutions....

Read More

January 15, 2025

In today’s competitive manufacturing landscape, automation is key to staying ahead. Auto Bag Placers, offered by Payper India...

Read More