- CSA-70 is designed to handle open-mouthed flat bags (without side gussets). Ideal for granular or high-density products which in turn ensures the stability of the filled bag. Capacity up to 700 bags/hour according to the product.

- CSA-75 is designed to handle open-mouthed flat bags (without side gussets). It has a bag accompaniment for powdery products that cause its instability. Capacity up to 500 bags/hour according to the product.

- CSA-95 version is suitable for handling bags with side gussets or PINCH bags. It incorporates a bag accompaniment for powdery products that cause instability, at the same time guaranteeing the bag stays horizontal in the case of PINCH bags. Capacity up to 800 bags/hour according to the product.

- CSA-90 is designed to handle open-mouthed flat bags (without side gussets). Ideal for granular or high-density products which in turn ensures the stability of the filled bag. Capacity up to 900 bags/hour according to the product

- CSA-100 is designed to handle open-mouthed flat bags (without side gussets). Ideal for granular or high-density products which in turn ensures the stability of the filled bag. Capacity up to 1,400 bags/hour according to the product.

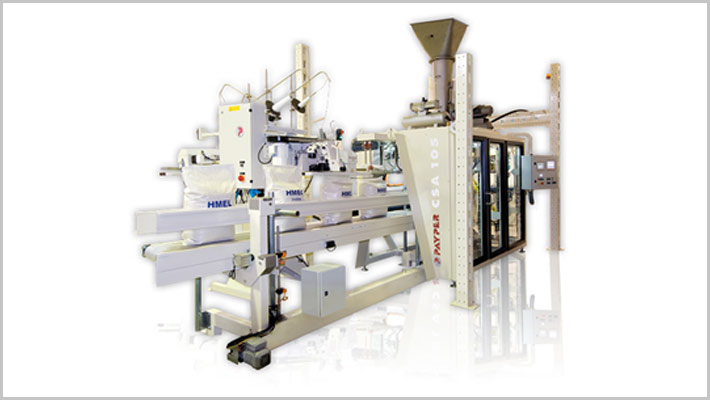

- CSA-105 version is suitable for handling bags with side gussets or PINCH bags. It incorporates a bag accompaniment for powdery products that cause instability, at the same time guaranteeing the bag stays horizontal in the case of PINCH bags. Capacity up to 1,600 bags/hour according to the product